Cracked concrete lintel is a mystery

By Jeanne Huber,

Q: The concrete lintel over one of our front windows has cracked. The house was built in 1989 and has wood framing, with brick facing on only the front of the house. We have been unable to find anyone to repair or replace it. Can we do this ourselves?

Rockville, Md.

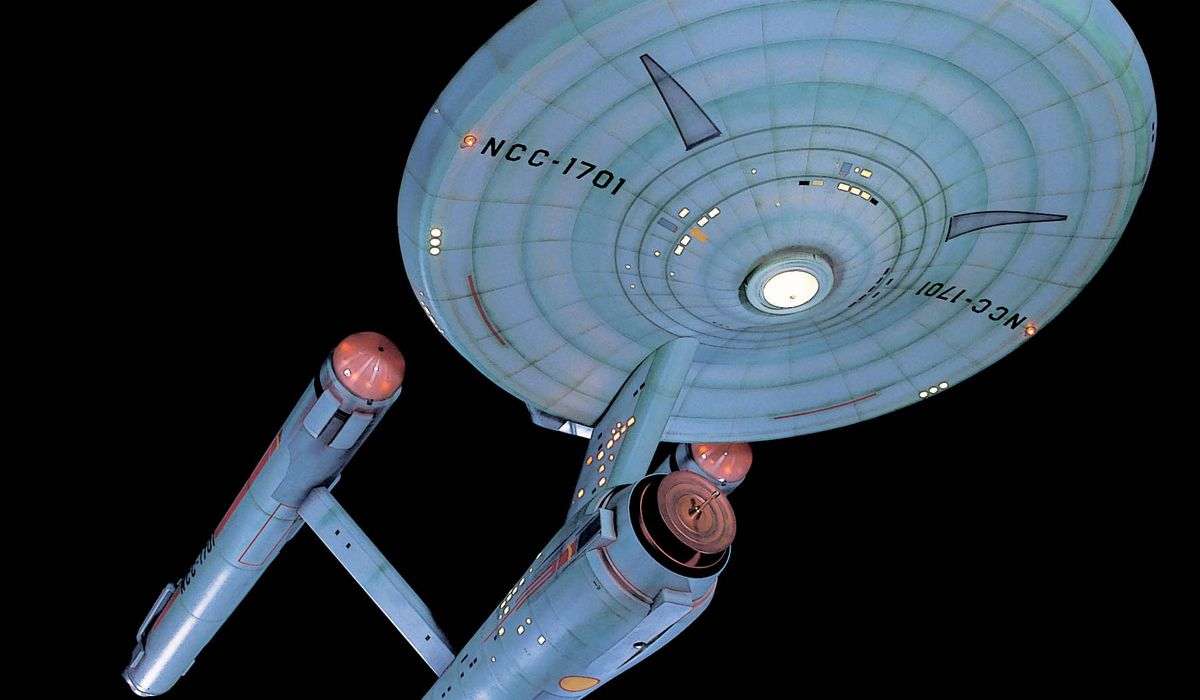

A: These cracks are a real head-scratcher. An experienced mason, a structural engineer and representatives of several trade associations that deal with concrete masonry all said it’s difficult to explain why horizontal cracks would occur as they show in the lintel in the picture you sent.

Precast concrete can sometimes crack because of problems in the manufacturing process, but “if there is a problem, you’d usually see that soon,” said Gabriela Mariscal, director of market segments and the person who answers calls for technical help for the National Concrete Masonry Association in Herndon, Va. (703-713-1900; ncma.org). She noticed that the cracks appear to be wider in the front than they are deeper into the concrete, and said the only explanation she could offer was there might be something pressing out against the lintel from inside the wall. She suggested calling a structural engineer for an assessment.

[How can I keep the crickets out of my old, damp garage?]

Hadi Rahnama, a professional engineer at HRA Structural Engineers in Potomac (301-315-0605; hrastructural.com), and Rogan Stearns, a registered professional engineer at Stearns Engineering in Rockville (301-294-9414; stearnsengineering.net), both said that, judging from the picture, it’s unlikely your house has a structural problem.

The lintel appears to be carrying only its own weight, Rahnama said in an email.

In a phone interview, Stearns said that if there was outward pressure on the lintel, there would typically also be diagonal cracks in the brick radiating out from the corners of the lintel. But the bricks on your house don’t show any cracks. If the lintel cracked because of excessive pressure from above, Stearns said, the cracks in the concrete would be vertical and in the middle of the span. It’s also possible that cracks in a lintel could be caused by steel reinforcing that’s rusting, because steel expands to 10 times its original size as it rusts, he said. “But then you would see the bottom surface falling off,” he said. In the picture, the bottom surface of the lintel looks fine.

If these were normal times and the company was still making house calls, Stearns could arrange an in-person inspection by his associate, who bills at $175 an hour. With travel time, that might take two hours, and another couple of hours might be invested in writing a letter with recommendations, bringing the fee to around $700. But the letter would probably just recommend patching the concrete and monitoring it to see whether the cracks reappear, Stearns said.

Based on this, you might want to get right to patching the concrete, with a big caveat that there are no guarantees the patches will hold. You could do this yourself, keeping costs at a minimum, or hire someone who specializes in small home-repair tasks.

Chad Corley, director of public relations for Quikrete, which makes concrete mixes and patching products, recommends using Quikrete Polymer Modified Structural Repair ($20.15 for a 20-pound tub at Home Depot). This product contains a pre-blended mixture of cement, sand and a polymer that helps it bond well and resist sagging and shrinking. It’s ideal for vertical repairs, Corley said in an email. It also provides a smooth finish that can be painted, which you’ll want to do after you patch to give the lintel a uniform look.

Hairline cracks don’t provide enough room for the fine sand in this mix; you should widen the cracks, so they are ⅜ to ½ an inch wide, but not wider. Use a chisel and hammer, and wear eye protection. Rather than chisel out a V shape, the widened cracks should be squared off, which helps the patch stay in place better. “Finally, the repair material should be applied so it extends beyond the lintel surface, so that when it’s thumbprint hard, it can be sculpted and smoothed with a margin trowel,” Corley said. He stressed, though, that if the cracks are happening because of a structural issue, no patching material will solve the problem permanently. That would also be the case if the cracks are happening because of the ingredients used in the concrete mix.

If patching doesn’t work, the only solution will be to find a masonry contractor to chip out the lintel and replace it. Felipe Alonso, owner of Alonso Construction Services in Rockville (240-205-6551; alonsoconstruct.com), said he suspects that moisture behind the lintel is the source of the problem, unless the cracks have been there since the beginning, in which case, the cause is probably an improper cement mix. After erecting scaffolding, he would first bolt on a temporary support to carry the weight of the bricks above, then chip out the lintel and see if there is water damage that needs to be dealt with. Then, he would install a new, precast lintel. The cost might range from $3,000 to $5,000, he said.

More from Lifestyle: How to replace damaged laminate on an old bedroom furniture set When old windows need new glazing around the panes My basement window well keeps filling with water. What can I do?